Recent Posts

Newsletter

Sign Up to get updates & news about us . Get Latest Deals from Walker's Inbox to our mail address.

- +1 (809) 801-2396

- info@acuapool.services

- Mon - Fri 08AM - 6PM

Sign Up to get updates & news about us . Get Latest Deals from Walker's Inbox to our mail address.

Hydraulic systems are integral to the efficient functioning of a building’s plumbing, heating, and cooling systems. These systems operate on the principle of fluid mechanics, utilizing fluids to transfer energy and facilitate various tasks within the building. The key components of hydraulic systems include pumps, pipes, valves, and tanks, each playing a critical role in maintaining the flow and pressure of the fluids involved.

Pumps are responsible for moving fluids through the system, generating the necessary pressure to ensure that water reaches various fixtures and appliances. The pipes serve as conduits for these fluids, connecting different parts of the hydraulic system and allowing for the distribution of water and other fluids throughout the building. Valves are essential in controlling the flow of fluids, enabling users to regulate water temperatures and maintain optimal pressure levels. Lastly, tanks are utilized for storing water or other fluids, serving as reservoirs that support the hydraulic system’s operations.

Regular inspections of hydraulic systems are essential for preventing failures and maintaining overall efficiency. Over time, wear and tear can occur, leading to leaks, pressure losses, or complete system failures. Identifying potential issues early through routine inspections can save substantial time and costs associated with repairs and downtime. Additionally, by ensuring that all components of a hydraulic system are functioning optimally, building operators can enhance energy efficiency, reduce waste, and prolong the lifespan of the system.

In summary, hydraulic systems are crucial in ensuring that a building operates smoothly and efficiently. Understanding their components and the importance of regular inspections can greatly contribute to the longevity and effectiveness of plumbing, heating, and cooling systems within any facility.

Acuapool stands out as a leader in hydraulic system inspections, primarily due to its unwavering commitment to quality and customer satisfaction. With years of experience in the industry, Acuapool has cultivated a team of qualified professionals who are well-versed in the nuances of hydraulic systems. This expertise allows them to conduct thorough inspections, identifying potential issues before they escalate into costly repairs. The knowledge possessed by Acuapool’s staff ensures that clients receive insightful advice tailored to their specific needs.

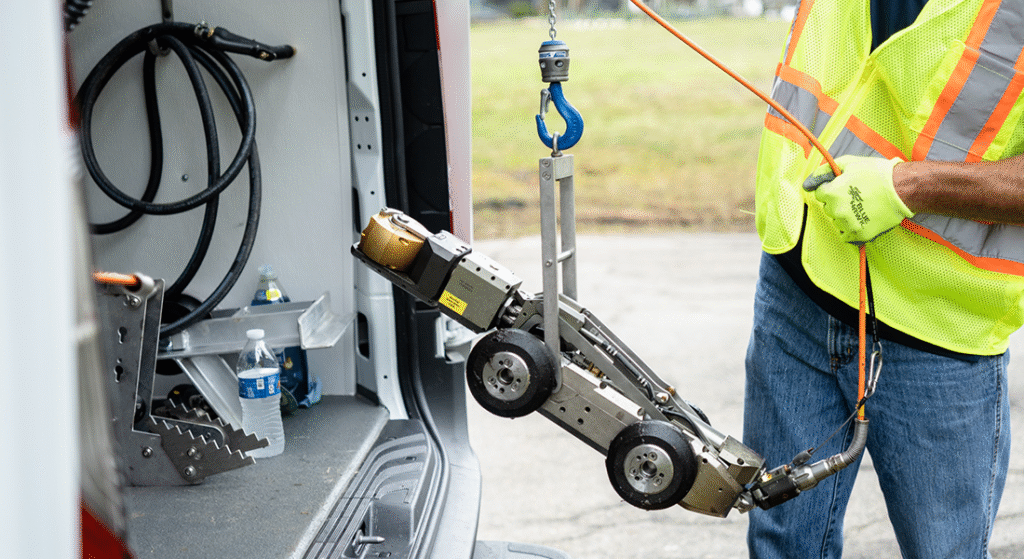

In addition to their skilled team, Acuapool employs cutting-edge technology and state-of-the-art equipment in their inspection processes. These tools not only enhance the accuracy of findings but also streamline the overall inspection process. Clients can expect reliable data that informs the health of their hydraulic systems, facilitating prompt decision-making. The use of advanced technology also positions Acuapool as a frontrunner, ensuring that every inspection meets or exceeds industry standards.

Another compelling reason to select Acuapool for hydraulic system inspections is their dedication to maintaining exceptional quality and safety standards. The organization ensures that all inspections are conducted in compliance with regulatory requirements, protecting clients from potential liabilities. This commitment not only enhances safety but also fosters trust in their services, assuring clients that their systems are in capable hands.

Furthermore, choosing Acuapool translates into cost-effective solutions for clients. By identifying issues early on, Acuapool helps to prolong the lifespan of hydraulic systems, ultimately leading to reduced maintenance costs. This proactive approach delivers significant long-term savings, showcasing the value of their services. In essence, Acuapool’s combination of expertise, advanced technology, safety, and economic benefits solidifies its position as the preferred choice for hydraulic system inspections.

When engaging Acuapool’s building hydraulic system inspection services, clients can anticipate a well-structured and thorough process designed to ensure the safety and efficiency of their hydraulic systems. The inspection begins with scheduling an appointment, during which clients can communicate specific concerns or requirements. This initial conversation is vital as it helps our technicians prepare for the visit and tailor the inspection according to the unique needs of the system.

On the day of the inspection, our experienced technicians arrive equipped with specialized tools necessary for a comprehensive assessment. The first step is a visual inspection of the hydraulic system, which includes checking for any apparent signs of wear, leaks, or corrosion. The technicians pay close attention to vital components, such as hoses, valves, pumps, and reservoir tanks, to ensure they meet safety standards.

Following the visual assessment, more advanced diagnostic tools are employed to gather data on the system’s performance. Techniques such as pressure testing and fluid analysis are utilized to detect inefficiencies or potential failure points that may not be visible to the naked eye. This part of the process is crucial, as it helps identify underlying issues that could lead to operational downtime or safety hazards if left unaddressed.

Throughout the inspection, all findings are meticulously documented. Our technicians compile detailed reports that include photographs, descriptions of any identified issues, and recommendations for repairs or maintenance. This documentation not only enhances transparency but also provides clients with a clear understanding of their hydraulic system’s condition. Once the inspection is complete, clients receive a comprehensive report, ensuring they are well-informed about their hydraulic system’s status and any necessary actions that may follow.

Acuapool’s commitment to customer satisfaction is further illustrated by their approach to after-service support. One of their clients from the construction sector noted that the thoroughness of ensuring post-inspection follow-ups was instrumental in maintaining sustained high performance of their hydraulic systems. The inspections not only fulfilled compliance requirements but also revealed opportunities for optimization that translated into tangible savings and operational improvements. This focus on delivering continuous value reinforces the necessity of professional inspection services in maximizing efficiency and safety within hydraulic systems.